Power grid studies

Arc flash Studies

Background

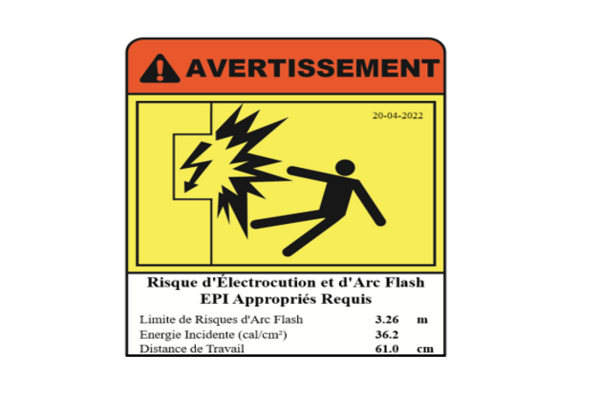

In industrial electrical facilities, the arc flask risk represents a major hazard for both operators and equipment. An arc flash can generate extreme temperatures, explosions, and severe burns for an operator. International regulations and standards (such as IEEE 1584 and NFPA 70E) now require a structured approach to assess and reduce this risk.

Requirement

Operators need to appreciate the level of arc flash hazard in their installations in order to:

- Protect personnel through the selection of appropriate personal protective equipment (PPE);

- Adapt intervention procedures;

- Optimise protection settings to reduce incident energy;

- Comply with regulatory and normative requirements.

Principle :

An arc flash study consists of:

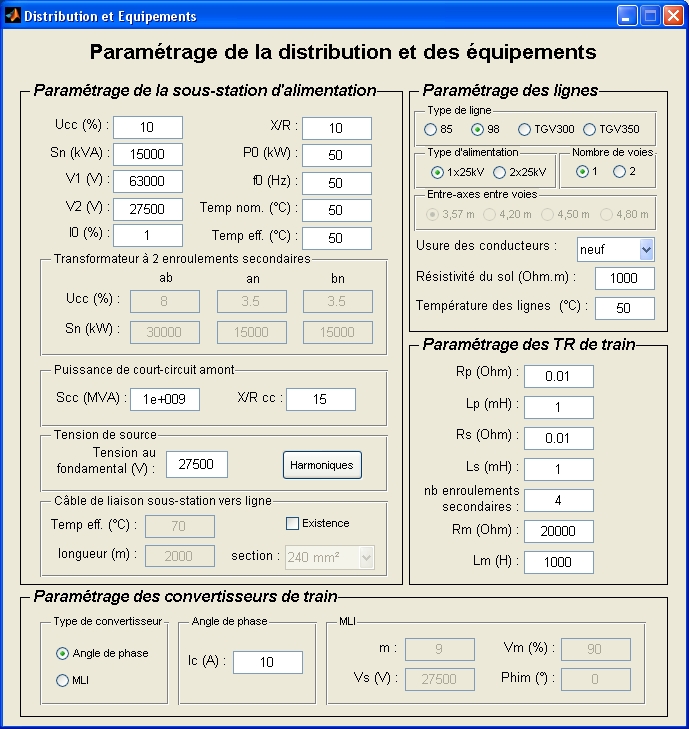

- Modelling the electrical equipment using a dedicated software (ETAP or Power Factory);

- Computing short-circuits currents and incident energy at various points in the facility;

- Determining safety distances and required PPE categories;

- Proposing corrective measures (reduction of protection clearing times, energy-limiting devices, etc.).

Results

At the end of the study, the client receives:

- A comprehensive report quantifying risk levels;

- Action plans to improve installation safety;

- Appropriate signage (arc flash labels to be affixed on switchboards or electrical panels).